When you think about solar power, you will likely picture solar panels installed on roofs, or large arrays of solar modules, silently generating clean electricity from America’s most abundant energy resource: sunlight. And while that image accurately represents the outcome, it does not tell the story of an entire industry that goes to work each day, enabling America’s sustainable energy future.

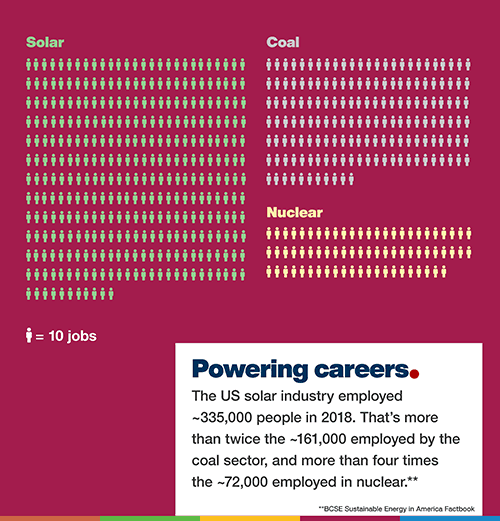

For over 11 years, Eric Hilbert has worked at the First Solar’s facility in Perrysburg, Ohio, now part of the Western Hemisphere’s largest solar manufacturing operation. An Ohioan and a US Navy veteran, he is one of 335,000 people estimated to have been directly employed by the American solar industry in 2018, according to the Sustainable Energy in America Factbook, published by the Business Council for Sustainable Energy. Put into context, the US coal and nuclear sectors together employed 233,000 people.

For over 11 years, Eric Hilbert has worked at the First Solar’s facility in Perrysburg, Ohio, now part of the Western Hemisphere’s largest solar manufacturing operation. An Ohioan and a US Navy veteran, he is one of 335,000 people estimated to have been directly employed by the American solar industry in 2018, according to the Sustainable Energy in America Factbook, published by the Business Council for Sustainable Energy. Put into context, the US coal and nuclear sectors together employed 233,000 people.

In his role as a Senior Facilities Site Manager, Eric represents a group of workers responsible for manufacturing solar technology in America that powers electricity generation both at home and abroad. Each year, manufacturers in the United States, including First Solar, produce over seven gigawatts of solar panels, equivalent in capacity to 28 average-sized, 250-megawatt (MW) coal power plants being built per year.

However, for Eric to effectively do his job, and for companies like First Solar to continue to represent American innovation in a global solar manufacturing industry dominated by competition from China, a complex supply chain employing thousands, needs to deliver.

First Solar operates a geographically diverse supply chain and spends approximately $1 billion a year in transactions with American businesses. From the CadTel semiconductor that forms the core of every First Solar module to the sheets of glass that safely encapsulate it, solar manufacturing is spurring innovation, investment, and the creation of jobs in America.

When First Solar expanded its manufacturing footprint in Northwest Ohio, it represented over $1 billion in cumulative investment, while creating approximately 500 new jobs. In addition to the direct costs of building and equipping a new factory, the investment also includes a new $265 million TCO (transparent conductive oxide) coated glass factory being built by the NSG Group in Toledo, Ohio, the company’s first new factory in the United States in 40 years.

First Solar’s contribution to the American economy does not stop there. In addition to over 2,500 direct jobs in the United States, the company’s operations indirectly support approximately 7,000 jobs across the country. For instance, the sand that NSG uses to manufacture the glass comes from Michigan, while the soda ash is sourced from Wyoming, creating valuable jobs in those states. The movement of raw materials to Ohio, and the finished modules from First Solar’s factories creates jobs for truckers, railroad workers, and logistics professionals.

The modules are shipped to sites around the country where engineers and construction workers install them on large-scale solar power plants, often using components such as mounting structures, cabling, and inverters sourced from other American companies.

Beyond solar manufacturing, construction, and operations ecosystem, clean solar electricity is helping drive prosperity in other industries. In many instances, large-scale solar power plants supply the energy needs of America’s largest, most innovative companies, supporting data centers that form the backbone of social media networks and the cloud, which in turn create hi-tech jobs. In others, they give American ranchers an additional source of revenue by leasing a portion of their land to build large-scale solar power plants, while protecting local ecosystems. And they even allow farmers the opportunity to graze their sheep under the arrays, keeping the sheep happy and allowing their shepherds to benefit from supplemental income.

Beyond solar manufacturing, construction, and operations ecosystem, clean solar electricity is helping drive prosperity in other industries. In many instances, large-scale solar power plants supply the energy needs of America’s largest, most innovative companies, supporting data centers that form the backbone of social media networks and the cloud, which in turn create hi-tech jobs. In others, they give American ranchers an additional source of revenue by leasing a portion of their land to build large-scale solar power plants, while protecting local ecosystems. And they even allow farmers the opportunity to graze their sheep under the arrays, keeping the sheep happy and allowing their shepherds to benefit from supplemental income.

But it is not enough. Solar has the potential to power a much larger share of American growth and prosperity, a potential that is now being tapped into by utility companies, and investors. And we believe that American solar should, in turn, be powered by American ingenuity and technology. That is why Eric and over two thousand of his colleagues go to work at First Solar each day, making the most of their days so that America can make the most of clean, reliable solar electricity.